3BHE023784R1023 PPD113B01-10-150000 ABB 控制器驱动单元是专门为ABB工业自动化控制系统设计的驱动组件。

该驱动单元的主要功能是接收控制器的指令,并将这些指令转换成能够驱动执行机构(如电机、气缸等)的信号。它具有高精度和高可靠性的特点,能够保证执行机构按照控制器的指令精确地执行动作。

此外,该驱动单元还具有多种保护和故障诊断功能,能够在发生故障时及时停机并发出警报,保护设备和人员安全。同时,该驱动单元还支持多种通信协议和接口标准,方便与其他的控制系统进行集成和互联。

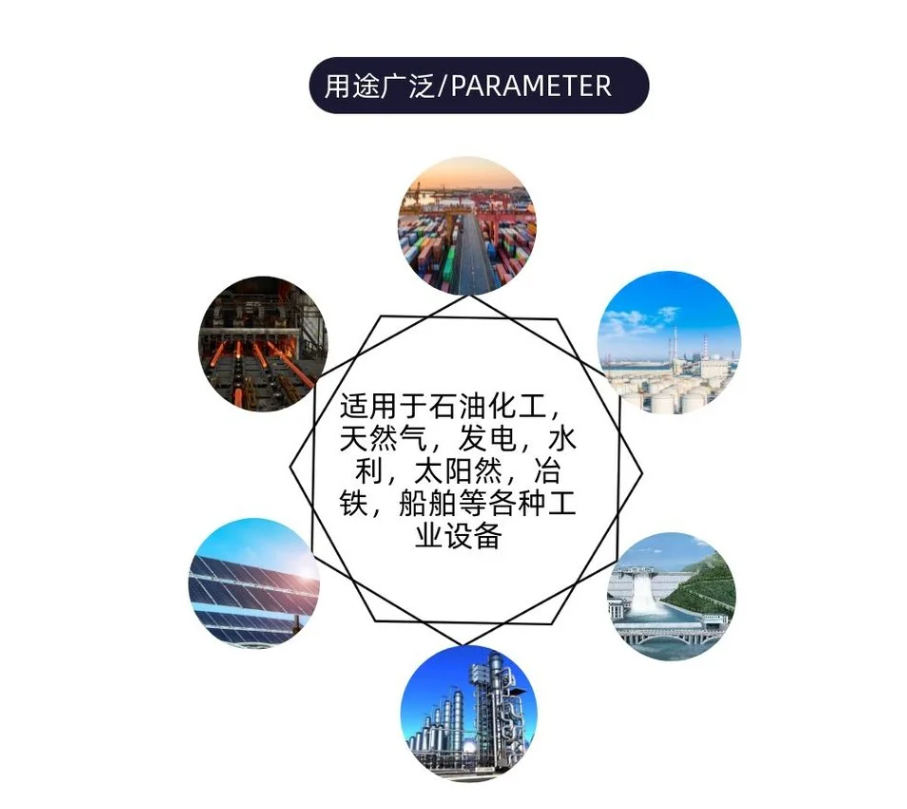

总的来说,3BHE023784R1023 PPD113B01-10-150000 ABB 控制器驱动单元是工业自动化控制系统中不可或缺的一部分,能够为各种自动化应用提供可靠、精准的控制支持。

控制器驱动单元的保护和故障诊断功能是通过多种方式实现的,主要包括以下几个方面:

综上所述,控制器驱动单元的保护和故障诊断功能是通过多种方式的综合应用实现的,这些功能能够提高工业自动化控制系统的可靠性和安全性。

Modbus是一种用于设备之间通信的应用层协议,主要用于交换自动化领域的典型数据。Modbus协议基于一个简单的包,称为协议数据单元 (PDU),由请求(由客户端发出)和响应(由服务器发出)组成。该协议规范定义了三种类型的 PDU:请求 PDU,包括:指定功能的代码(功能代码,1 字节)和功能特定数据(功能数据,可变字节数);响应 PDU,包括:请求对应的功能码(Function Code,1字节)和响应特定数据(响应数据,可变字节数);异常响应 PDU,包括:请求对应的功能码+0x80(128),(错误码,1字节)以及指定异常的代码(异常代码,1 字节)。

每个功能都分配了一个特定的功能代码。这些功能代码的范围是 1-127(十进制),因为129-255(即 1+128-255)代表错误代码的范围。功能码分为以下三类:协议里规定好的功能,用户也可以自定义功能、Public、保证是唯一的,并指定公开记录的明确定义的功能。这些由社区验证并且存在一致性测试、读离散输入、读写线圈、读输入寄存器、读写保持寄存器、User-Defined、可用于用户定义的函数,因此它们的代码可能不是唯一的。该规范为用户定义的函数定义了代码范围 65-72 和 100-110、保留、这些目前被一些公司用于遗留产品,不能公开使用函数的文档包括:函数的描述(即它的用途)、它的参数和返回值(包括可能的异常)。

此外,Modbus协议也实现了串行通信。最常见的串行通信形式是异步串行网络通信,应用层协议直接在串行接口和串行通信标准之上运行。其中,Modbus协议通过附加字段扩展了PDU,将PDU包装到一个带有标头和错误校验和的包中。这种实现使用的是RTU帧或ASCII码帧。RTU帧以二进制传输以实现更高的密度,而ASCII码帧被编码为每个字节两个ASCII字符,代表字节的十六进制表示法。

3BHE023784R1023 PPD113B01-10-150000 ABB controller drive unit is a drive component specifically designed for ABB industrial automation control systems.

The main function of this driving unit is to receive instructions from the controller and convert these instructions into signals that can drive the executing mechanism (such as motors, cylinders, etc.). It has the characteristics of high precision and high reliability, which can ensure that the executing mechanism executes actions accurately according to the instructions of the controller.

In addition, the driver unit also has various protection and fault diagnosis functions, which can stop the machine in a timely manner and issue an alarm in the event of a fault, protecting equipment and personnel safety. At the same time, the driver unit also supports multiple communication protocols and interface standards, facilitating integration and interconnection with other control systems.

Overall, the 3BHE023784R1023 PPD113B01-10-150000 ABB controller driver unit is an indispensable part of industrial automation control systems, providing reliable and accurate control support for various automation applications.

The protection and fault diagnosis functions of the controller driver unit are achieved through various methods, mainly including the following aspects:

Sensor monitoring: The controller drive unit is usually equipped with multiple sensors, such as temperature sensors, current sensors, pressure sensors, etc., to monitor the operating status of the drive unit. By monitoring the data of these sensors in real-time, the controller driver unit can promptly detect abnormal situations and take corresponding protective measures.

Fault diagnosis algorithms: The drive unit of the controller usually integrates fault diagnosis algorithms, which can analyze the operating status of the drive unit in real time. By comparing historical and current data, abnormal situations are identified, and faults are classified and located.

Exception handling mechanism: When the sensor detects an abnormal situation or the fault diagnosis algorithm identifies a fault, the controller driving unit will take corresponding exception handling mechanisms, such as shutdown, reducing output torque, switching backup modules, etc., to protect the safety of equipment and personnel.

Alarm and log recording: The controller driver unit will also emit alarm signals through sound, light, and other means to remind operators to handle faults in a timely manner. At the same time, it will record fault information and related data in a log, facilitating subsequent analysis and processing.

Communication protocols and interface standards: The controller driver unit usually supports multiple communication protocols and interface standards, such as Modbus, Profibus, EtherNet/IP, etc. Through these communication protocols and interface standards, the controller driver unit can interact with other control systems to achieve remote monitoring and fault diagnosis.

In summary, the protection and fault diagnosis functions of the controller driver unit are achieved through multiple comprehensive applications, which can improve the reliability and safety of industrial automation control systems.

18030183032