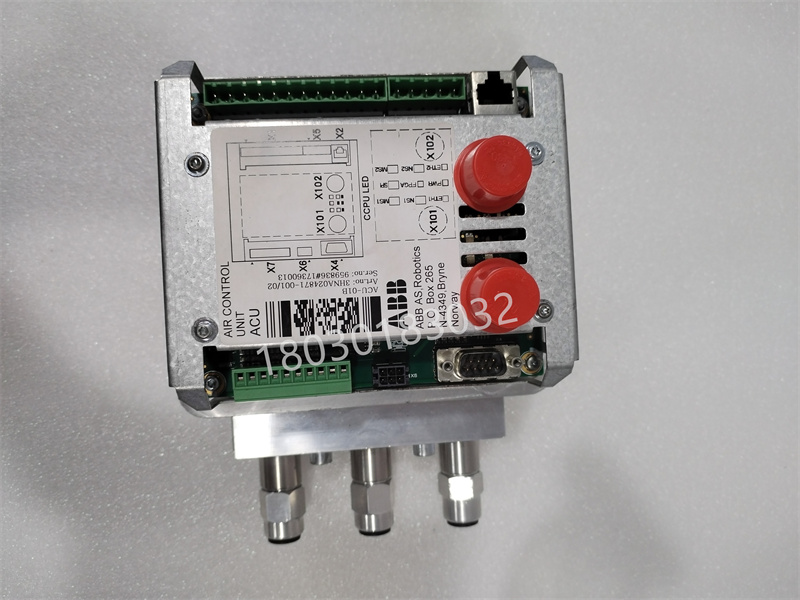

ABB ACU-01B 3HNA024871-001 机器人备件是一款高性能、多功能的工业自动化控制模块,

专为机器人控制、过程自动化及驱动集成等中大型自动化系统设计。

核心硬件组成:

存储与安全:

扩展选项:

协作机器人(Cobot)多轴运动控制:

风电变流器并网控制:

CNC机床加工过程监控:

ABB ACU-01B 3HNA024871-001 robot spare parts is a high-performance, multifunctional industrial automation control module,

Specially designed for medium to large-scale automation systems such as robot control, process automation, and drive integration.

1、 Core functions and features

Multi axis motion control: supports the drive of rotating and linear brushless motors, suitable for single axis motion control and multi axis synchronization applications, meeting the needs of industrial robots for high precision and high dynamic response.

Real time data processing and complex logic operations: Equipped with a dual core ARM Cortex-A9 processor (with a main frequency of 1.2GHz) and FPGA (Xilinx Artix-7), the real-time task processing latency is less than 100 μ s, and it supports dual system switching between Linux RTOS and VxWorks.

Diversified communication interfaces: Integrated dual port Gigabit Ethernet (supports Profinet/EtherCAT), CAN FD, RS-485/232 interfaces, Ethernet ports support Redundant Ring Network (MRP), and communication latency is less than 1ms.

High precision I/O expansion: Provides 4-channel high-speed DI/DO (24V DC, response time less than 500ns) and 2-channel AI/AO (16 bit, ± 10V/4-20mA), digital input supports PNP/NPN compatibility, and analog sampling rate reaches 100kS/s.

Safety and reliability design: compliant with the Safety Torque Off (STO) standard, with built-in overcurrent, overvoltage, and undervoltage protection functions; Dual power redundant input (24V DC ± 20%, supports hot swapping) and TVS surge protection circuit (SMBJ30CA) ensure stable system operation.

2、 Hardware architecture and scalability

Core hardware composition:

The processor and FPGA are interconnected at high speed through the AXI bus, with a data throughput of up to 2Gbps.

The communication module PCB is independently wired with a distance of ≥ 3mm from the power layer to reduce electromagnetic interference.

The I/O module is connected to the main control board through an isolated LVDS interface, with an isolation voltage of 3kV.

Storage and Security:

Equipped with 2GB DDR3 RAM and 16GB eMMC (industrial grade, supporting -40 ° C to+85 ° C), with a write life of ≥ 5000 erase cycles.

Data encryption complies with FIPS 140-2 standard, and ECC verification is configured in critical data storage areas to prevent bit flipping.

Extension options:

Supports integration of 5G modules (such as Quectel RM500Q-GL) or Wi Fi 6 (QCA6391) through Mini PCIe slots.

AI/AO channels can be connected to daughter cards through an extended bus interface (compatible with ETG.1000.6 standard), supporting up to 16 channels.

The emergency stop button interface integrated with SIL 3 certification (such as Pilz PNOZ s3) is isolated through a safety optocoupler (ACPL-K30T).

3、 Application scenarios and advantages

Multi axis motion control of collaborative robot (Cobot):

By connecting 8 servo drives through EtherCAT and implementing feedforward compensation algorithm using FPGA, the trajectory tracking error is less than 0.01mm.

Embedded installation in the robot control cabinet, connected to the motor encoder through an M12 X-connector.

Grid connected control of wind power converter:

Collect grid voltage/current (through Hall sensor interface), run phase-locked loop (PLL) algorithm, and control IGBT module switch.

Add EMC filters (such as TDK ZJYS81R5-2W) to meet the IEC 61800-3 standard.

Monitoring of CNC machining process:

Synchronize the collection of vibration sensor (4-20mA) and temperature sensor (PT100, requiring external signal conditioning module) signals, and upload them to the MES system through OPC UA.

Modify the ADC input filter parameters (cut-off frequency reduced from 1kHz to 100Hz) to match low-frequency signals.

4、 Environmental adaptability and durability

Working temperature range: -20 ° C to+60 ° C (base model), optional heat dissipation fin mounting holes (M3 thread, spacing 50.8mm) can be selected for high temperature environments (≥ 60 ° C).

Protection level: Certified with IP65 protection, it can reach IP67 after installing Humisay 1B31 paint and sealing ring, and is suitable for harsh conditions such as humidity and vibration.

Anti interference capability: transient immunity ± 4kV (IEC 61000-4-5), electrostatic protection ± 15kV (IEC 61000-4-2), ensuring stable operation in complex electrical environments.

5、 Software support and debugging tools

Built in debugging software: MINT Workbench provides automatic debugging wizard and software oscilloscope function, simplifying parameter configuration and troubleshooting.

Industrial protocol stack: Supports OPC UA, MQTT over TLS, requires loading ABB Ability ™ Edge software package.

Time synchronization: Reserve IRIG-B time code input interface (P102, 3.81mm spacing terminal), supporting nanosecond level time synchronization.

18030183032