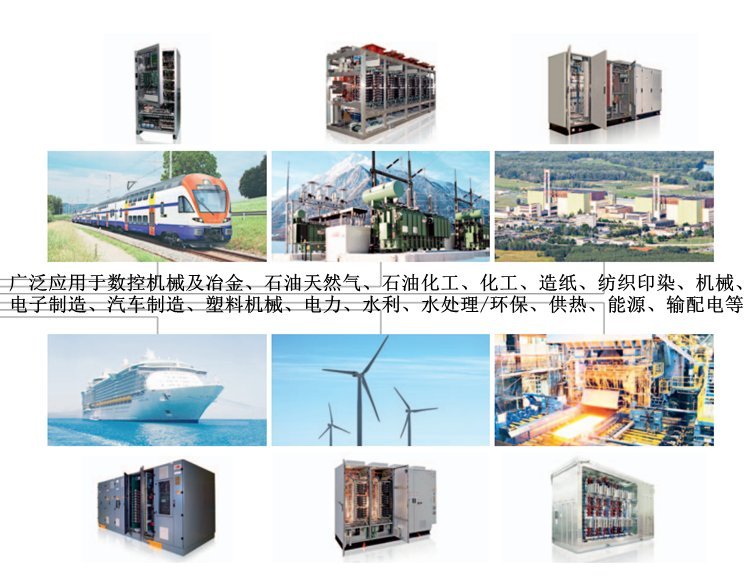

产品技术参数: UUD148AE02ABB 电流测量控制器模块

1、各自技术发展的起源

计算机是为了满足快速大量数据处理要求的设备。硬件结构方面,总线标准化程度高,兼容强,软件资源丰富,特别是有实时操作系统的支持,故对要求快速、实时强、模型复杂和计算工作量大的工业对象的控制占有优势。

集散系统从工业自动化仪表控制系统发展到以工业控制计算机为中心的集散系统,所以其在模拟量处理、回路调节方面具有一定优势,初期主要用在连续过程控制,侧重回路调节功能。

PLC是由继电器逻辑系统发展而来,主要用在离散制造、工序控制,初期主要是代替继电器控制系统,侧重于开关量顺字控制方面。

近年来随着微电子技术、大规模集成电路技术、计算机技术和通信技术等的发展,PLC在技术和功能上发生了飞跃。在初期逻辑运算的基础上,增加了数值运算、闭环调节等功能,增加了模拟量和PID调节等功能模块;运算速度提高,的能力赶上了工业控制计算机;通信能力的提高发展了多种局部总线和网络(LAN),因而也可构成为一个集散系统。特别是个人计算机也被吸收到PLC系统中。

PLC在过程控制的发展将是—智能变送器和现场总线,暨向下拓展功能,开放总线。

在微电子技术发展的背景下,从硬件的度来看,PLC、工业计算机、集散系统(DCS)之间的差别正在缩小,都将由类似的一些微电子元件、微处理器、大容量半导体存储器和I/O模件组成。编程方面也有很多相同点。

由于PLC和计算机属于两类产品,经过几十年的发展都形成了自身的装置特点和软件工具。实际上的区别继续存在。

PLC用编程器或计算机编程,编程语言是梯形图、功能块图、顺序功能表图和指令表等。集散系统自身或用计算机结构形成组态构成开发系统环境.

特别提出的是与STD总线工控机的区别,无论从维修、安装和模件功能都很相似。PLC适用于黑模式下运行,但在线运行时若要进行较大的程序修改,其能力略逊于STD工控机,但是从开关量控制而言,PLC的能优于STD工控机。

总的来说,在选择控制器时,首先要从工程要求、现场环境和经济等方面考虑。没有什么控制器完善,也没有哪种产品差,只能说选择适用的产品。

PLC自问世以来,经过20多年的发展,在美国、欧洲、等工业发达国家已成为重要产业,197年世界PLC的销售额为25亿美元,此后每年以20%左右的速度递增。进入90年代以来,世界PLC的年平均销售额在55亿美元以上,其中我国约占1%。当前,PLC在市场上已成为受欢迎的工业控制畅销产品,用PLC设计自动控制系统已成为世界潮流

Product technical parameters: UUD148AE02ABB current measurement controller module

1. Origin of respective technological development

Computers are devices designed to meet the requirements of fast and massive data processing. In terms of hardware structure, the bus has a high degree of standardization, strong compatibility, and abundant software resources, especially with the support of real-time operating systems. Therefore, it has advantages in controlling industrial objects that require fast, strong real-time, complex models, and high computational workload.

Distributed systems have evolved from industrial automation instrument control systems to distributed systems centered around industrial control computers. Therefore, they have certain advantages in analog processing and loop regulation. Initially, they were mainly used in continuous process control, with a focus on loop regulation functions.

PLC is developed from relay logic systems and is mainly used in discrete manufacturing and process control. In the initial stage, it mainly replaced relay control systems, with a focus on switch quantity sequential control.

In recent years, with the development of microelectronics technology, large-scale integrated circuit technology, computer technology, and communication technology, PLC has made a leap in technology and functionality. On the basis of initial logical operations, functions such as numerical operation and closed-loop adjustment have been added, as well as functional modules such as analog quantity and PID adjustment; The computing speed has improved, and the ability to catch up with industrial control computers; The improvement of communication capabilities has led to the development of various local buses and networks (LANs), which can also form a distributed system. Especially personal computers have also been incorporated into PLC systems.

The development of PLC in process control will be intelligent transmitters and fieldbuses, as well as downward expansion of functions and open buses.

In the context of the development of microelectronics technology, from a hardware perspective, the differences between PLCs, industrial computers, and distributed systems (DCS) are narrowing, and they will all be composed of similar microelectronic components, microprocessors, large capacity semiconductor memories, and I/O modules. There are also many similarities in programming.

Due to the fact that PLC and computers belong to two categories of products, they have formed their own device characteristics and software tools after decades of development. The actual difference continues to exist.

PLC is programmed using a programmer or computer, with programming languages such as ladder diagrams, function block diagrams, sequential function table diagrams, and instruction tables. The distributed system itself or the development system environment formed by computer structure configuration

Specifically, the difference between STD bus industrial control computers is that they are very similar in terms of maintenance, installation, and module functions. PLC is suitable for operating in black mode, but if significant program modifications are required during online operation, its ability is slightly inferior to that of STD industrial control computers. However, in terms of switch value control, PLC's performance is superior to that of STD industrial control computers.

Overall, when selecting a controller, the first consideration should be given to engineering requirements, on-site environment, and economy. There is no perfect controller, and there is no product that is inferior. It can only be said to choose the applicable product.

Since its inception, PLC has become an important industry in industrialized countries such as the United States, Europe, and other countries after more than 20 years of development. In 197, the world's sales revenue of PLC was 2.5 billion US dollars, and since then, it has been increasing at a rate of about 20% annually. Since the 1990s, the average annual sales of PLC in the world have exceeded 5.5 billion US dollars, with China accounting for about 1%. Currently, PLC has become a popular industrial control best-selling product in the market, and using PLC to design automatic control systems has become a world trend

这里有更多你需要的产品:UUD148AE02 ABB 电流测量控制器模块

PM803F 3BDHO00530R1

ABB

PM866-2 3BSE050201R1

ABB

PM866-2 3BSE050201R1

ABB

PM864AKO1 3BSE018161R1

ABB

PM864A

ABB

PM866A

ABB

PM510V16 3BSE008358R1

ABB

PM864

ABB

PM864A

ABB

PM865K01 3BSE031151R1

ABB

PM865K01 3BSE031151R1

ABB

PM866

ABB

PM783F 3BDH000364RO001

ABB

PM864AK01 3BSE018161R1

ABB

PM864AK013BSE018161R1

ABB

PM866

ABB

PM783F 3BDH000364R0002

ABB

PM15oV08 3BSEO09598R1

ABB

PM150V08 3BSE009598R1

ABB

AC800M 3BSE053240R1 PM891

ABB

PM861K013BSE018105R1

ABB

PM511V16 3BSE011181R1

ABB

PM633

ABB

PM861K01

ABB

PM861AKO1

ABB

PM861AKO1

ABB

PM861AKO1

ABB

PM803F

ABB

PM802F

ABB

PM802F

ABB

PM802F

ABB

PM825-1

ABB

PM820-2

ABB

PM820-1

ABB

PM861AK01

ABB

PM803F

ABB

PM866A-2

ABB

PM803F

ABB

PM864AKO1-eA

ABB

INNPM12

ABB

INNPM12

ABB

PM645B

ABB

PM633

ABB

PM632

HONEYWELL

51402455-100 MP-DNCFO2-200

HONEYWELL

51402455-100 MP-DNCF02-201

HONEYWELL

51305896-200 NIM MODEM

HONEYWELL

SPS5785 51198651-100

Honeywell

SPS5710 51199929-100

Honeywell

SPS5710-2-LF 51198685-100

HONEYWELL

CC-IP010151410056-175

HONEYWELL

cC-IP0101 51410056-175

HONEYWELL

05701-A-0550

HONEYWELL

SC-TCMX0151307198-175

HONEYWELL

SC-PCMX0151307195-175

HONEYWELL

05704-A-0144

HONEYWELL

05701-A-0361

HONEYWELL

05704-A-0145

Honeywell

05074-A-012205704-A-0121 05704-A-0131

HONEYWELL

05701-A-0361

HONEYWELL

05704-A-0146

HONEYWELL

CC-TDILO1

HONEYWELL

cC-TDILO1

Honeywell

SPS571351199930-100

HONEYWELL

261A1812P012

HONEYWELL

GR-4C-DC24v

HONEYWELL

GR-2C-AC230V

HONEYWELL

GR-2C-DC24V

HONEYWELL

FC-PSU-UNI2450U V2.1

HONEYWELL

05701-A-0302

HONEYWELL

SPS5710 51199929-100

HONEYWELL

FC-PSU-UNI2450U V2.1

HONEYWELL

CC-TDILO1

HONEYWELL

CC-TAOX11

HONEYWELL

CC-TAIXO1

Honeywell

CC-TDOB11

HONEYWELL

CC-MCARO2

18030183032