PM633是一款可编程逻辑控制器,其特点和应用场景如下:

特点:

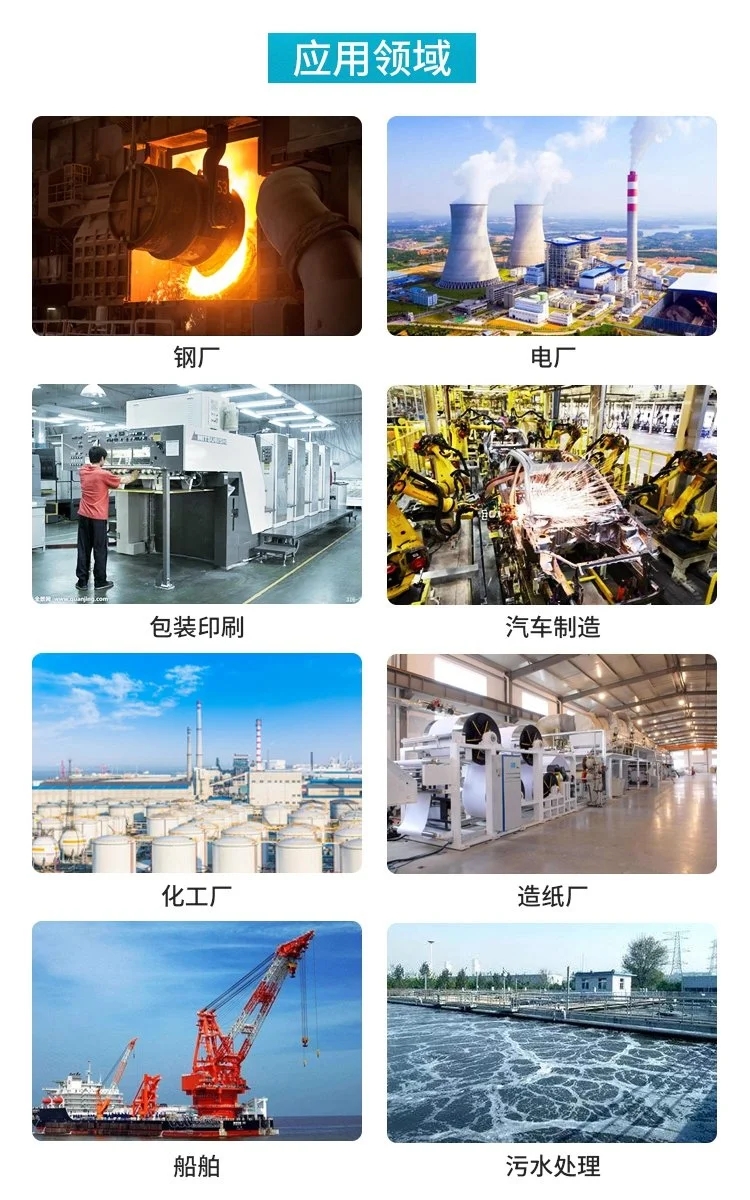

应用场景:

PM633广泛应用于各种需要逻辑控制的应用场景,如工业自动化、智能制造、能源管理、楼宇自动化等。它可以作为整个自动化系统的核心控制器,协调各个设备的工作,实现整个系统的自动化运行。

保护作用:

PM633 is a programmable logic controller, with the following characteristics and application scenarios:

Features:

High performance: Using high-performance processors and large capacity memory, it can quickly process a large number of control instructions and data, achieving efficient control and monitoring.

Multiple communication interfaces: supporting multiple communication protocols and interface standards, facilitating data exchange and control operations with other devices, sensors, and actuators, achieving information sharing and collaborative work.

High reliability: Using high-quality materials and manufacturing processes, it has high stability and reliability, and can operate stably for a long time in harsh industrial environments.

Easy to use and integrate: With standardized interfaces and connection methods, it is convenient for users to install and maintain. Supports multiple expansion modules and options, and can be flexibly configured and expanded according to user needs.

Powerful control capability: capable of controlling various industrial equipment, such as valves, pumps, fans, compressors, etc., to achieve automated control and monitoring.

High safety: With multiple safety protection functions, such as overcurrent, overvoltage, undervoltage, etc., it can ensure the safety of equipment and personnel.

Flexible configuration method: Users can flexibly configure PM633 according to their actual needs, such as setting control parameters, adjusting control strategies, etc., to meet various industrial automation control needs.

Application scenario:

PM633 is widely used in various application scenarios that require logical control, such as industrial automation, intelligent manufacturing, energy management, building automation, etc. It can serve as the core controller of the entire automation system, coordinating the work of various devices, and achieving the automation operation of the entire system.

Protective effect:

Overload protection: When the device is overloaded, the controller will automatically reduce the output power or turn off the power to protect the device from overload damage.

Short circuit protection: When a short circuit occurs, the controller can automatically cut off the power or reduce the current to prevent equipment damage.

Temperature protection: The controller is equipped with a built-in temperature sensor, which can monitor the device temperature in real time. When the temperature exceeds the set value, it will automatically reduce the current or turn off the power to prevent equipment overheating and damage.

Fault diagnosis and positioning: The controller has the function of fault diagnosis and positioning, which can timely detect and locate faults, making it convenient for users to repair and maintain.

Lightning protection: The controller has a built-in lightning protection function, which can effectively avoid damage to the system caused by lightning strikes.

Current limiting protection: Limiting the current flowing through the module within a safe range to prevent excessive current from causing damage to the module.

Overvoltage protection: When the output voltage is too high, the controller will automatically adjust the output voltage to a safe range to prevent damage to the load caused by high voltage.

Undervoltage protection: When the output voltage is too low, the controller will automatically adjust the output voltage to a safe range to prevent damage to the load caused by low voltage.

Phase loss protection: When the input power supply is in phase loss, the controller will automatically cut off the power supply or reduce the current to prevent equipment damage.

Output over temperature protection: When the internal temperature of the module is too high, the controller will automatically reduce the output power or turn off the power to protect the module from high temperatures.

Over temperature protection: When the temperature of the heat sink is too high, the controller will automatically reduce the output power or turn off the power to protect the heat sink from high temperatures.

Phase sequence protection: When the input power phase sequence is incorrect, the controller will automatically cut off the power or reduce the current to prevent equipment damage.

Overvoltage and undervoltage protection: When the input voltage is too high or too low, the controller will automatically adjust the input voltage to a safe range to prevent abnormal voltage from causing damage to the module.

18030183032