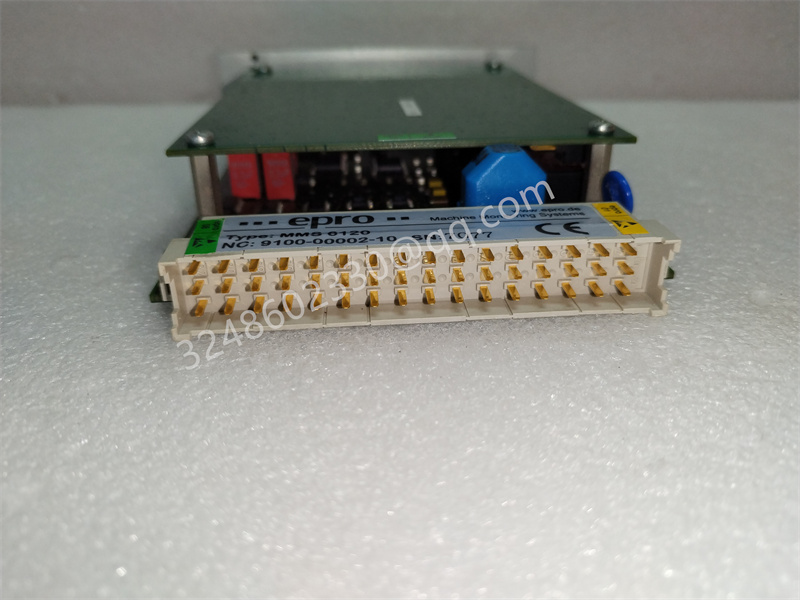

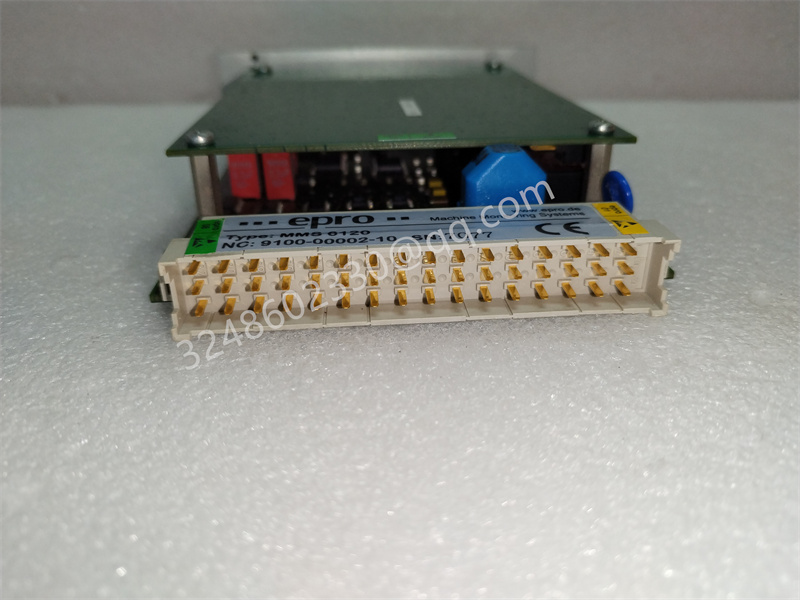

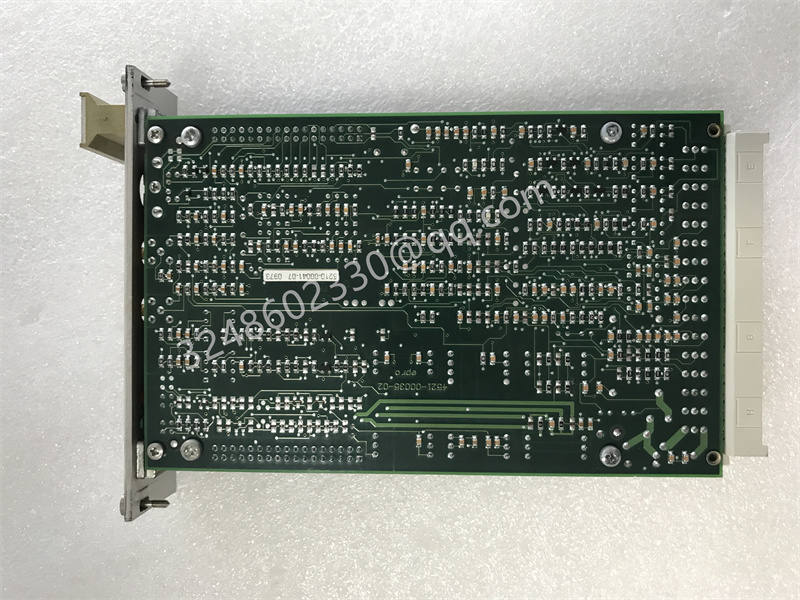

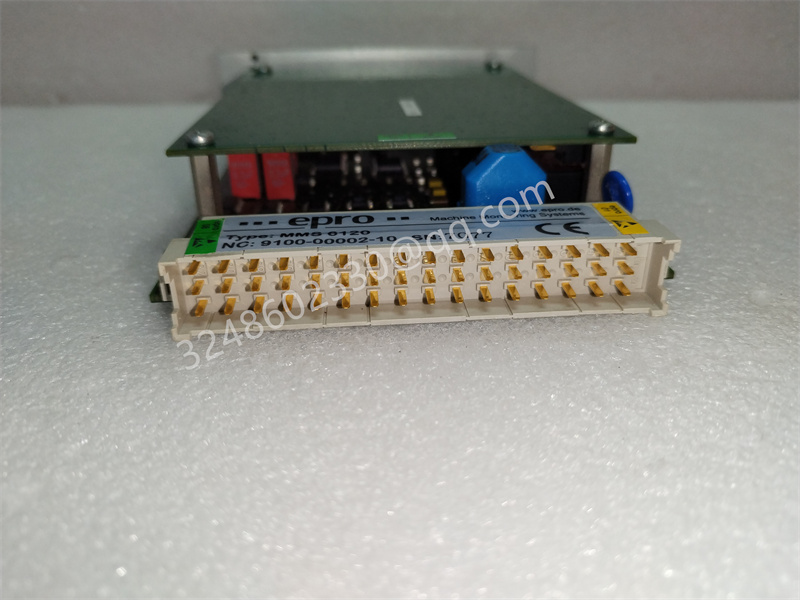

EMERSON MMS6120 模块

MMS6120 是艾默生(Emerson)旗下德国 EPRO 品牌推出的一款双通道轴承振动监测器,常用于旋转机械的振动、

位移或速度信号的连续监测与保护。该模块结构紧凑、性能稳定,广泛应用于汽轮机、压缩机、泵、风机等关键设备的状态监测系统中。

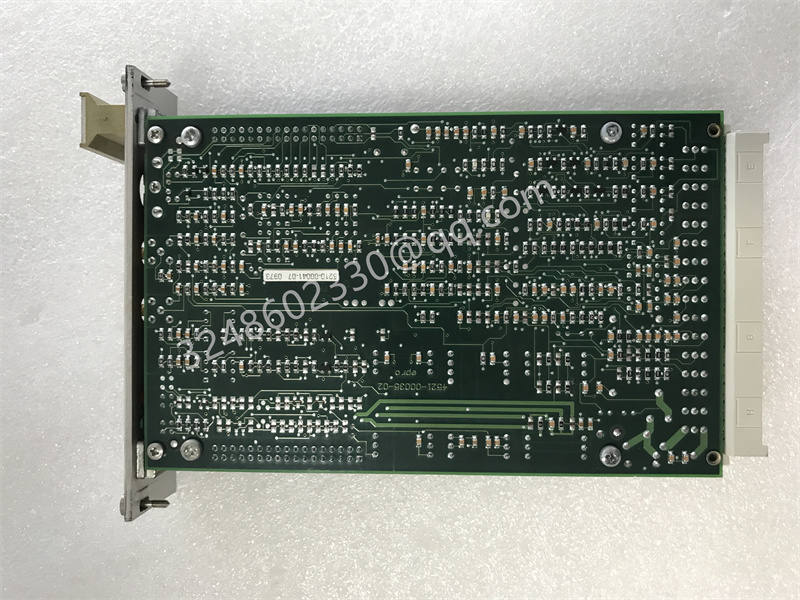

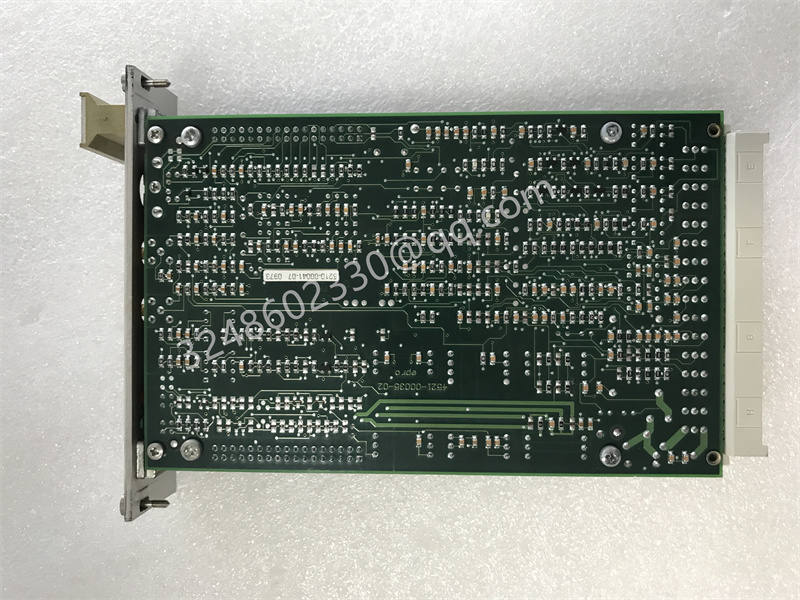

坚固耐用:模块化铝壳设计,抗振动、抗冲击,工作温度 -20 °C … +70 °C,适应复杂工业环境。

重量 约 0.3 kg

风机健康管理:结合趋势分析软件,预测轴承寿命,指导维护计划。

EMERSON MMS6120 module

Product Overview:

MMS6120 is a dual channel bearing vibration monitor launched by Emerson's German EPRO brand, commonly used for vibration of rotating machinery

Continuous monitoring and protection of displacement or velocity signals. This module has a compact structure and stable performance, and is widely used in the status monitoring system of key equipment such as steam turbines, compressors, pumps, and fans.

Main features and advantages

Dual channel monitoring: Two sets of vibration or displacement sensors can be connected simultaneously, supporting parallel analysis and improving monitoring efficiency.

Industrial grade accuracy: using 16 bit ADC, high measurement accuracy, good repeatability, suitable for micrometer level vibration detection.

Broadband response: The frequency range covers 0.5 Hz-10 kHz, taking into account both low-frequency shaft vibration and high-frequency bearing fault characteristics.

Multiple outputs: Provides 4-20 mA, 0-10 V, relay alarm, and Modbus/PROFIBUS-DP communication interface for easy access to DCS or PLC.

On site programmability: Parameter settings such as range, alarm points, and filters can be completed through the front panel buttons or software tools without the need for disassembly.

Durable and sturdy: Modular aluminum shell design, resistant to vibration and impact, working temperature -20 ° C...+70 ° C, suitable for complex industrial environments.

technical specifications

Model MMS6120

Number of channels 2

Input type IEPE/ICP acceleration, velocity, or displacement sensor

Measurement range 0-50 mm/s (speed) or 0-500 µ m (displacement)

Frequency range 0.5 Hz -10 kHz

Analog output 4-20 mA/0-10 V

Digital interfaces RS-485 Modbus RTU, PROFIBUS-DP

Relay output 2-channel programmable alarm relay

Working power supply 24 V DC ± 20%

Working temperature -20 ° C...+70 ° C

Storage temperature -40 ° C...+85 ° C

Size 120mm × 75mm × 45mm

Weight approximately 0.3 kg

Typical applications

Turbine vibration monitoring: installed on the bearing seat, real-time collection of shaft vibration and tile vibration, triggering interlock shutdown.

Compressor protection: Monitor early failures of rolling bearings to prevent shaft holding accidents.

Remote monitoring of pump station: Upload vibration data to SCADA through Modbus to achieve unmanned operation.

Fan Health Management: Combining trend analysis software to predict bearing life and guide maintenance plans.

Related products

MMS6312: Portable vibration collector, suitable for on-site inspection and temporary monitoring.

AMS 6500 ATG: Emerson AMS Mechanical Health Platform, which can be networked with MMS612 for centralized diagnosis.

EPRO PR6423: Equipped with eddy current sensors for shaft displacement measurement, forming a complete monitoring circuit with MMS612.

MMS6120 provides an economical and reliable online vibration monitoring solution for rotating equipment with high precision, dual channels, and rich interfaces.

18030183032