HONEYWELL 900A16-0001 霍尼韦尔输出模块是一款重要的工业自动化产品,主要用于DCS(分散控制系统)中的模拟量输入。以下是对该模块的详细介绍:

一、基本信息

产品名称:霍尼韦尔HC900输入输出模块

产品型号:900A16-0001

品牌:Honeywell(霍尼韦尔)

类型:AI卡(模拟量输入卡),高电平输入卡

通道数:16通道

二、产品特点

模块化设计:该模块采用模块化设计,易于安装和维护。

高度集成:作为HC900系统的一部分,该模块与系统的其他组件紧密集成,提供混合处理、逻辑和顺序控制算法与数据采集功能。

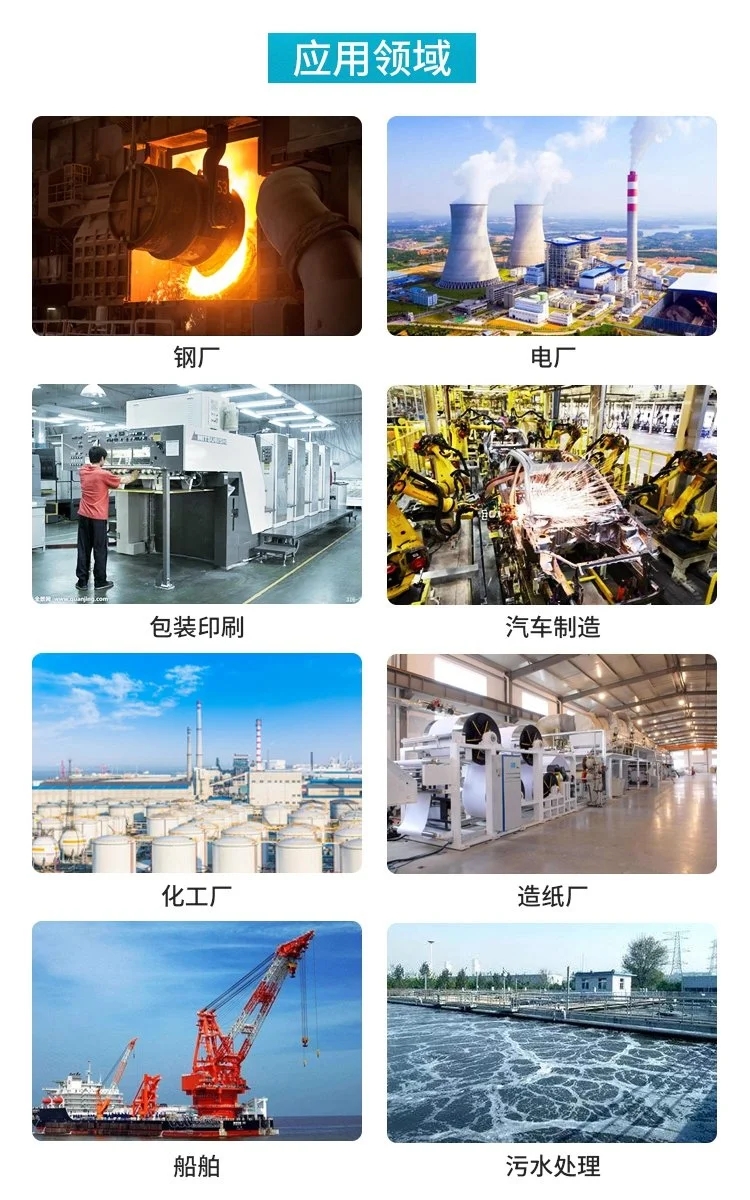

广泛适用性:适用于多种工业应用,如制造商品熔炉控制、高压器冷冻干燥器、环境舱、制剂/生物技术、发酵桶、制陶玻璃、干燥炉、玻璃熔炉/前炉/玻璃韧化炉、食品和饮料巴氏杀菌器等。

易于配置:使用基于Windows的Hybrid Control Designer软件工具,可以图形化地配置控制器和可选项,节省组态时间和成本。

三、技术规格

输入/输出点:具有1920个输入/输出点,支持多种类型的输入/输出槽机架。

控制回路:HC900系统具有32个控制回路,适用于不同的控制需求。

通讯方式:支持以太网、点对点通讯、串行Modbus RTU等多种通讯方式。

电源和接口:通常与HC900系统的电源和接口模块配合使用,确保系统的稳定运行。

HONEYWELL 900A16-0001 Honeywell output module is an important industrial automation product mainly used for analog input in DCS (Distributed Control System). The following is a detailed introduction to the module:

1、 Basic Information

Product Name: Honeywell HC900 Input/Output Module

Product model: 900A16-0001

Brand: Honeywell

Type: AI card (analog input card), high-level input card

Number of channels: 16 channels

2、 Product Features

Modular design: This module adopts a modular design, which is easy to install and maintain.

Highly integrated: As part of the HC900 system, this module is tightly integrated with other components of the system, providing mixed processing, logic, and sequential control algorithms and data acquisition functions.

Wide applicability: Suitable for various industrial applications, such as manufacturing commodity furnace control, high-pressure freeze dryer, environmental chamber, formulation/biotechnology, fermentation tank, ceramic glass, drying furnace, glass furnace/front furnace/glass toughening furnace, food and beverage pasteurizer, etc.

Easy to configure: Using the Windows based Hybrid Control Designer software tool, controllers and options can be graphically configured, saving configuration time and cost.

3、 Technical specifications

Input/output points: With 1920 input/output points, it supports multiple types of input/output slot racks.

Control circuit: The HC900 system has 32 control circuits, suitable for different control requirements.

Communication methods: Supports multiple communication methods such as Ethernet, point-to-point communication, serial Modbus RTU, etc.

Power and Interface: Usually used in conjunction with the power and interface modules of the HC900 system to ensure stable operation of the system.

18030183032