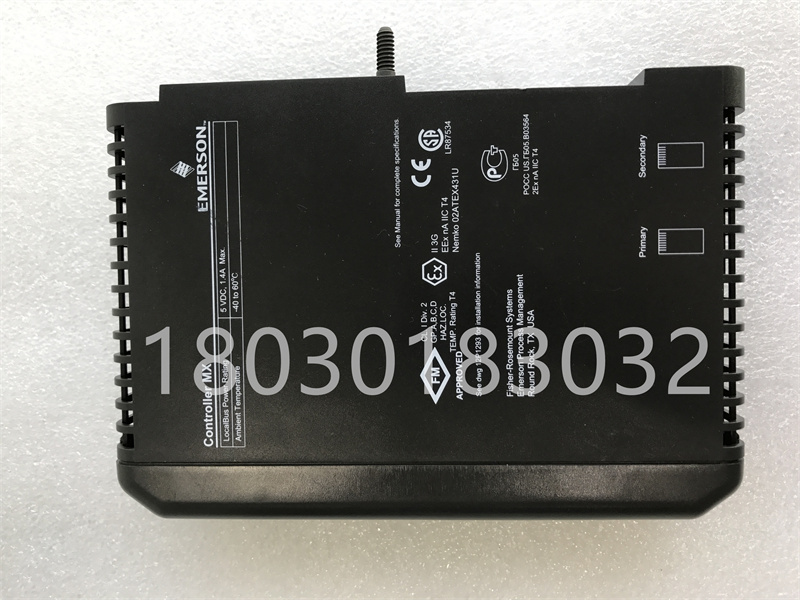

EMERSON VE3007 DeltaV MX 控制器

EMERSON VE3007 DeltaV MX 控制器是 Emerson 推出的一款高性能工业自动化控制器,属于 DeltaV 系列。

它结合了最新的软硬件技术,为用户提供高可靠性、高性能、易维护的工业自动化解决方案。

存储温度范围:-40°C 至 +85°C。

冗余架构:支持1:1冗余,提高可用性,现有MD/MD Plus或MQ控制器可在线升级。

提高生产力:

未来准备:随着系统增长,可扩展软件许可证以增加分配给DeltaV控制器的设备信号标签(DSTs)数量,从50个扩展到1500个DSTs,控制策略复杂性和控制模块扫描速率决定整体控制器性能。

EMERSON VE3007 DeltaV MX Controller

product overview

The EMERSON VE3007 DeltaV MX controller is a high-performance industrial automation controller launched by Emerson, belonging to the DeltaV series.

It combines the latest software and hardware technologies to provide users with highly reliable, high-performance, and easy to maintain industrial automation solutions.

technical specifications

Working voltage: 24V DC.

Monitoring current: Bus current ≤ 1mA, power supply current ≤ 6mA.

Action current: Bus current ≤ 4mA, power supply current ≤ 35mA.

Output capacity: DC24V/1A (the sum of the maximum output capacities of two groups is DC24V/1A).

Output control mode: pulse, level (relay normally open/normally closed passive contact output, relay pull in time is 10 seconds when pulse starts).

Operating environment: Temperature range of -10 ℃ to+55 ℃, relative humidity ≤ 95%, no condensation.

Size: 263 × 58 × 28mm, weight approximately 4.3kg.

Communication protocol: Supports multiple protocols (such as HART, MODBUS, etc.) and is compatible with multiple interface types (such as DIN rail, panel installation, etc.).

Power consumption: 2W.

User memory: 96MB.

Working temperature range: -40 ° C to+70 ° C.

Storage temperature range: -40 ° C to+85 ° C.

Functional Features

High reliability: Using high-quality materials and manufacturing processes to ensure long-term stable operation in harsh industrial environments.

High performance: Strong processing capability, fast response speed, capable of handling complex industrial automation tasks.

Modular design: convenient for users to install, replace, and maintain, reducing the difficulty of use and maintenance costs.

Multiple output types: Supports relay output, transistor output, and other output types to meet different application requirements.

Protection function: It has overcurrent, overvoltage, undervoltage and other protection functions, effectively protecting the module itself and connected devices.

Easy to monitor and maintain: Provides a user-friendly interface and easy-to-use monitoring tools to facilitate remote monitoring and fault diagnosis for users.

Adaptability: Provide larger capacity controllers for applications that require more control capacity, with twice the control capacity, user configurable memory, and DST counting.

Redundant architecture: Supports 1:1 redundancy to improve availability, existing MD/MD Plus or MQ controllers can be upgraded online.

Improve productivity:

Self identification: The DeltaV controller can automatically identify itself to the DeltaV control network without the need for a dip switch or configuration, achieving plug and play functionality.

Self positioning: The LED lights on the front panel of the controller can flash, making it easy to quickly locate the physical position of the controller.

Automatic I/O detection: The controller can identify all I/O interface channels on the subsystem, reducing configuration related worthless engineering.

Connecting electronic wiring: Starting from DeltaV v14.3, CHARMs connected through CHARM I/O cards (CIOC) can be assigned to MX controllers, simplifying the process of adding I/O to existing controllers.

Usability:

Powerful Control: The DeltaV controller manages all control activities of the I/O interface channels and all communication functions with the regional control network, providing powerful control structures such as continuous control function block diagrams, sequential function diagrams, and stage logic, and is enhanced through user-defined structured text algorithms. The controller executes control strategies within 100 nanoseconds and can communicate up to 4000 outliers per second.

Data protection: All control parameters that are changed online are automatically stored for subsequent upload to the engineering database, and the system always retains a complete record of all online change data.

Cold start: In the event of a power failure, the controller can automatically restart, completely autonomously, as the entire control strategy is stored in the controller's NVM RAM. Just set the restart state of the controller to the current condition.

Flexibility:

Advanced Operations: The MX controller supports DeltaV batch options as well as advanced control features such as neural networks and model predictive control.

Data channel: The controller is capable of transmitting intelligent HART signals from on-site devices ® The information is transmitted to any workstation node in the control network, enabling users to remotely manage HART information in HART or FOUNDATION Fieldbus devices using applications such as AMS Device Manager.

Future preparation: As the system grows, software licenses can be extended to increase the number of Device Signal Tags (DSTs) allocated to DeltaV controllers, from 50 to 1500 DSTs. The complexity of control strategies and the scanning rate of control modules determine the overall controller performance.

application area

The EMERSON VE3007 DeltaV MX controller is widely used in the following fields:

Industrial automation: used for monitoring and controlling various production processes, including temperature, pressure, flow rate, liquid level, and other parameters.

Energy production and distribution: used in the power, oil, and gas industries to monitor the operational status of power generation equipment, pipelines, storage tanks, and facilities.

Environmental monitoring: used to monitor various environmental parameters in the atmosphere, water, and soil.

Pharmaceutical and Life Sciences: Used to monitor and control the production processes, experimental conditions, and equipment status in pharmaceutical production and life science research.

Food and beverage industry: used to monitor temperature, humidity, pressure, and other parameters in food processing and beverage production.

Transportation: In the field of traffic management and vehicle control, it is used to monitor traffic flow, vehicle location, and status.

Building automation: used for intelligent control systems in buildings, including sensors and modules for temperature, lighting, safety, etc.

Water treatment and sewage treatment: used to monitor and control various parameters in the process of water treatment and sewage treatment.

18030183032