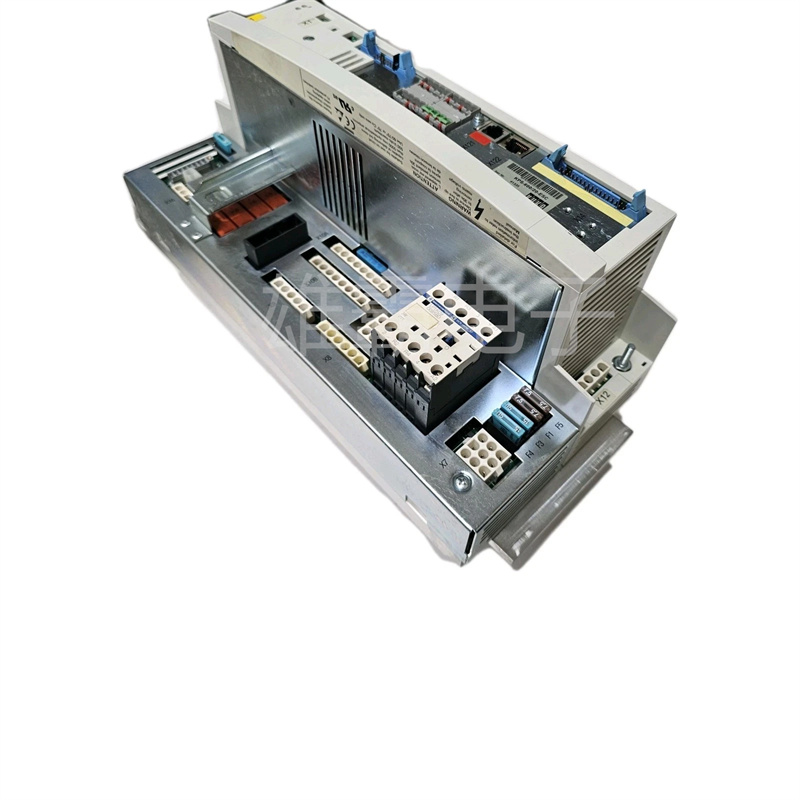

KUKA KPS-600/20-ESC 是一款高性能的驱动电源模块,专为 KUKA 工业机器人设计,广泛应用于自动化生产线、机器人系统和其他工业设备中。

技术规格

额定功率:600 W。

额定电压:20 V DC。

输出电流:30 A。

效率:>95%。

功率密度:20 kW/L。

工作温度:-10°C 至 50°C。

存储温度:-20°C 至 60°C。

防护等级:IP65。

输入电压:3相 AC 400-480V,50/60Hz。

输出电压:DC 600V。

重量:约 4.7 kg。

尺寸:200mm x 120mm x 100mm。

特点

高效率:采用先进的拓扑结构和高效率器件,最大效率可达 95%。

高功率密度:功率密度高达 20 kW/L,体积小巧,节省空间。

高可靠性:采用工业级设计,能够在恶劣的环境中可靠运行。

多种保护功能:具备过载保护、短路保护、过温保护和输入电压保护等功能,确保设备安全运行。

易于使用:提供友好的人机界面,方便操作和设置。

智能化控制:能够根据机器人的实际需求提供适量的电力输出,避免能源浪费。

应用场景

工业机器人:为机器人提供稳定的电力供应,确保机器人的正常运行。

自动化生产线:用于驱动自动化生产线中的各种设备。

物流设备:适用于物流自动化系统中的电机驱动。

激光加工:为激光加工设备提供稳定的电源。

电焊:用于电焊设备的电源供应。

维修与维护

故障诊断:使用 KUKA 提供的诊断工具或软件,对电源模块进行故障诊断,重点关注电源供应、输出电压、电流等关键参数。

拆卸与检查:在确定故障位置后,小心拆卸电源模块,检查是否有物理损坏或烧焦痕迹,并使用万用表和示波器等工具测试电路板上的元器件。

组装与测试:修复或更换损坏的部件后,重新组装并进行测试,确保模块恢复正常工作状态。

KUKA KPS-600/20-ESC is a high-performance drive power module designed specifically for KUKA industrial robots, widely used in automated production lines, robot systems, and other industrial equipment. technical specifications Rated power: 600 W. Rated voltage: 20 V DC. Output current: 30 A. Efficiency:>95%. Power density: 20 kW/L. Working temperature: -10 ° C to 50 ° C. Storage temperature: -20 ° C to 60 ° C. Protection level: IP65. Input voltage: 3-phase AC 400-480V, 50/60Hz. Output voltage: DC 600V. Weight: Approximately 4.7 kg. Size: 200mm x 120mm x 100mm. characteristic High efficiency: Adopting advanced topology and high-efficiency devices, the maximum efficiency can reach 95%. High power density: With a power density of up to 20 kW/L and a compact size, it saves space. High reliability: Adopting industrial grade design, it can operate reliably in harsh environments. Multiple protection functions: equipped with overload protection, short circuit protection, over temperature protection, and input voltage protection to ensure the safe operation of the equipment. Easy to use: Provides a user-friendly interface for easy operation and setup. Intelligent control: capable of providing appropriate power output according to the actual needs of the robot, avoiding energy waste. Application scenarios Industrial robots: Provide stable power supply for robots to ensure their normal operation. Automated production line: used to drive various equipment in automated production lines. Logistics equipment: suitable for motor drive in logistics automation systems. Laser processing: providing stable power supply for laser processing equipment. Welding: Used for power supply of welding equipment. repairs and maintenance Fault diagnosis: Use diagnostic tools or software provided by KUKA to diagnose faults in the power module, with a focus on key parameters such as power supply, output voltage, and current. Disassembly and Inspection: After determining the fault location, carefully disassemble the power module, check for physical damage or burnt marks, and use tools such as multimeters and oscilloscopes to test the components on the circuit board. Assembly and testing: After repairing or replacing damaged components, reassemble and test to ensure that the module returns to normal working condition.

18030183032