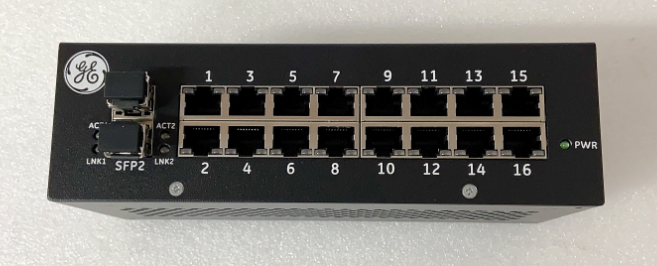

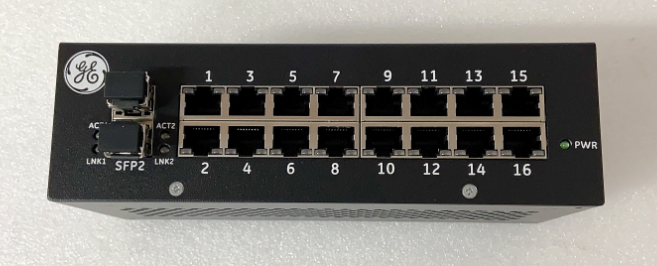

GE MPU55 工业交换机

GE MPU55 工业交换机是一款高性能的工业网络交换机,专为工业自动化和控制系统设计。它具备高可靠性、高效数据处理能力和多种通信协议支持,广泛应用于各种工业场景。

技术规格

型号:MPU55 369B1860G0026。

处理器:高性能 CPU,支持实时控制和复杂计算。

内存:256MB RAM,4GB 存储器。

工作温度:-40°C 至 70°C。

存储温度:-55°C 至 85°C。

相对湿度:5% 至 95%(非冷凝)。

防护等级:IP67。

尺寸:150 mm x 100 mm x 50 mm。

重量:约 3 kg。

功能特点

工业级设计:适用于恶劣工业环境,确保高可靠性和稳定性。

多种通信协议:支持以太网、Profibus、Modbus 等,便于与其他设备集成。

可编程:支持多种编程语言,包括梯形图、结构化文本和功能块图。

高精度控制:适用于电机控制和其他需要精确控制的应用。

冗余设计:增强系统正常运行时间和可靠性。

安全功能:提供高安全级别的功能,适用于关键应用。

应用场景

工业自动化:用于工厂自动化设备、生产线控制系统。

能源管理:在发电厂、变电站等能源领域。

交通运输:用于铁路、地铁等交通控制系统。

污水处理:作为控制系统的一部分,实现精确控制。

机器人通信:支持机器人之间的数据交换和通信。

数据采集与监控系统(SCADA):用于数据采集和监控。

分布式控制系统(DCS):作为网络连接的关键设备。

Ge mpu55 industrial switch Ge mpu55 industrial switch is a high-performance industrial network switch designed for industrial automation and control systems. It has high reliability, efficient data processing capability and multiple communication protocol support, and is widely used in various industrial scenarios. technical specifications Model: mpu55 369b1860g0026. Processor: high performance CPU, supporting real-time control and complex computing. Memory: 256MB ram, 4GB memory. Operating temperature: -40 ° C to 70 ° C. Storage temperature: -55 ° C to 85 ° C. Relative humidity: 5% to 95% (non condensing). Protection grade: IP67. Dimensions: 150 mm x 100 mm x 50 mm. Weight: about 3 kg. Functional features Industrial grade design: suitable for harsh industrial environment, ensuring high reliability and stability. Multiple communication protocols: support Ethernet, PROFIBUS, MODBUS, etc. for easy integration with other devices. Programmable: support multiple programming languages, including ladder diagram, structured text and function block diagram. High precision control: suitable for motor control and other applications requiring precise control. Redundancy design: enhance the normal operation time and reliability of the system. Security function: it provides functions with high security level and is applicable to key applications. Application scenarios Industrial automation: used for factory automation equipment and production line control system. Energy management: in power plants, substations and other energy fields. Transportation: used for railway, subway and other traffic control systems. Sewage treatment: as a part of the control system, accurate control is realized. Robot communication: support data exchange and communication between robots. Data acquisition and monitoring system (SCADA): used for data acquisition and monitoring. Distributed control system (DCS): as the key equipment of network connection.

18030183032